|

Sintra® color choices

In many cases, you can easily accomodate your

aesthetic desires by just buying pre-colored

Sintra® (the color is uniform through the

thickness of the material). If your creation will

spend much time outdoors or under bright lights,

however, you're probably best off sticking with

white material. Colored Sintra® is not UV

stable -- the colors will fade over time, and the

material itself will get brittle. Contrast this to

white Sintra®, which is relatively resistant to

UV light; I've read that it will last 2-4 years

outdoors. You should also consider sticking to

white material (or at least light colors), if your

'bot will be involved in BEAM

competition under Halogen lights. Due to

Sintra®'s low softening temperature, your 'bot

will warp fairly readily if lights are sufficiently

near and / or bright.

Marking on Sintra®

You'll eventualy scribble on your material, if not

as part of your 'bot's final look, at least while

you're laying out lines to cut along. I've found in

my tinkering that "permanent" markers work very

well with Sintra®; pencils mark the material

reasonably well (well enough for layout work);

water-based markers are a complete waste of your

time (water-based ink "beads" on the material). I

wouldn't recommend attempting any sort of iron-on

transfer (Sintra® softens at 150° F, while

copier / printer toner won't generally melt below

about 250° F). Adhesive stickers and tape seem

to stick well to the material.

Painting Sintra®

For the most part, Sintra® takes paint

well, with no primer being required. As for

chemical compatibility, Sintra will tolerate the

majority of paints well. In particular, I have

tested out Sintra® with discount store spray

enamel, and they get along just fine.

Edge treatment

If you're going to paint Sintra®, how you

handle the edges can be a bit problematic (since

they're porous). You'll need to do a bit of extra

work on the edges of Sintra® if you want them

to look as smooth as the face sheets after

painting. I tried a number of edge treatments,

following up with a quick coat of spray paint.

|

|

|

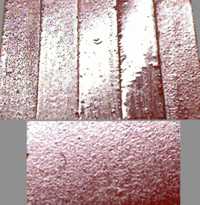

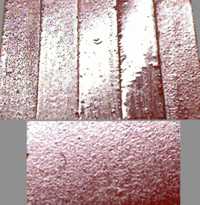

Top: painted Sintra® edges; from

left, untreated, 2 coats of paint (sanded

between coats with 220 grit sandpaper),

white glue, cyanoacrylate, PVC pipe

cleaner.

Bottom: painted Sintra® face

sheet

|

As you can see, if you're going to paint

Sintra®, doing nothing to the edges leaves them

looking a bit rough compared to the faces. The best

match is yielded by giving the edges a quick wipe

with PVC pipe cleaner (although this needs to be

done with some care, as this cleaner can scar the

face sheets if you get too much on them). A simpler

approach is to just apply two coats of paint, with

a bit of sanding between them. A thin coat of

cyanoacrylate or even white glue, followed by a

quick sanding with 220 grit sandpaper can also be

used as a quick sealant, if you prefer a glossier

looking edge.

Conclusions

Sintra® is an affordable and promising

BEAMbot

building material, so long as you know and work

within its limitations. It's easy to cut, easily

shaped, fairly stiff for its weight, and is

compatible with a number of adhesives and most

commercially available paints.

|

For more

information

|

|

A very good source of detailed information

on Sintra® is the official manual,

which I've downloaded (in PDF format) from

Alusuise's

web site and mirrored here.

As for web sites on Sintra®, the

most informative one that I've found is

Sintra®

Online. It has tables of load

capacities, material properties, etc. The

site itself is written in Spanish, but the

technical information tables are all in

English. If you'd like to peruse the

Spanish material, but can't read the

language, just remember to use the

fish...

|

|